Delivering the wood of choice for yachts, aircraft, musical instruments and more. Much more.

Cambria (William Fife III, 1928) sporting the tallest Sitka spruce mast in the world

Introduction.

Sitka spruce is what we do and who we are.

Alaska Yellow Cedar is our second nature.

Sitka spruce is the world’s strongest wood specie in relation to its weight. This makes it the wood of choice for yacht spars, wooden aircraft, musical instruments, archery and more. For most companies Sitka spruce is a specialty specie, not for us, it is what we do and who we are.

We have a unique position in Sitka spruce as we are the only company in the world which owns sawmills both at the source in the Northwest Pacific Region as well as Europe where most of it find its use. We work with foresters in the remote regions to find the best logs, we inspect forest stands, personally inspect each individual log before it comes to our sawmill in Northern Canada.

Our sawmill in Northern Canada was built to cut Sitka spruce for the most demanding users in the world, the people who demand the finest quality, who value precision cut and consistent grading. We build our mill to serve the builders of masts for boats and yachts, the artisans and factories building musical instruments, the restorers of vintage yachts and aircraft.

Our sawmill in Holland was built to process and remanufacture wood with dedication for the final use. Here we plane, saw, grade and saw again until the board hits the quality and grade as ordered.

Our dedication to Sitka spruce, our specialization and passion for excellence had helped us build a unique know-how on Sitka spruce. We hope to be your go-to-place for Sitka spruce and discuss your projects and needs.

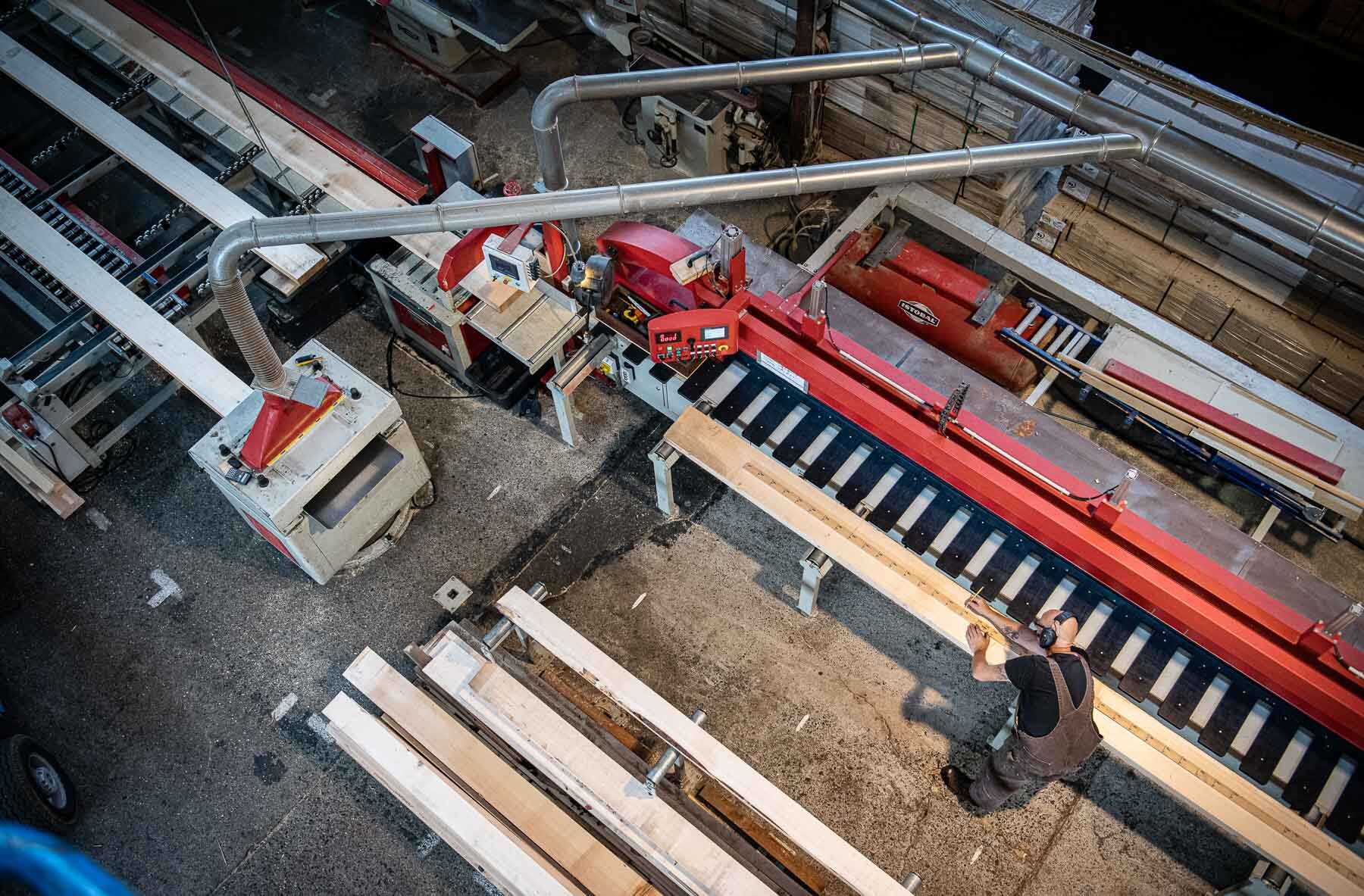

Production line at the Dutch mill

Projects.

Where our timbers come to life.

The timbers sawn at our mill in Northern Canada come to life at our remanufacturing mill in Holland. Each part of the tree has its optimum use and so each timber coming to the mill is processed for appearance, length, strength and weight. Each of the most common applications has its own rules and so over 20 different grades have been developed to make sure the wood you order is perfectly fit for purpose.

Our timbers.

Sitka spruce is what we do and who we are.

Sitka spruce is what we do and who we are. Quality and graded for purpose, we exclusively source Sitka spruce from the very best regions in the Pacific Northwest territories of Canada and Alaska. Our company is unique as we personally inspect the forest from which the Sitka spruce originates, we then ship the logs to our own sawmill in Northern British Columbia where they are quarter sawn and prepared for shipment to our remanufacturing mill in The Netherlands. In the Netherlands we have a dedicated saw and planer line to grade and prepare the Sitka for specific purposes; Up to 12 meter lengths for masts and spars of yachts, aircraft spruce for new and vintage aero planes, tone wood for musical instruments as well as a range of specialty projects and products.

Full list of Sitka spruce products . . .

Specialty products

- Timbers up to 60ft – 18 meter length

- Mast & spar timber

- Aircraft spruce

- Sounding board stock

- Guitar tops

- Custom veneers

- Deck beam and stringers

- Custom veneers

- Arrow shafts (Traditional Archery)

- Fine furniture grade

- Table slabs

Sitka spruce Veneers

For a range of special applications we manufacture sawn veneers in Sitka spruce. From a basic 1,5m long and 5mm veneer for deck beam laminates to extraordinary and rare 12 meter long veneers for vacuum bagging on carbon spars. We also keep a limited volume of sliced veneers in 0,8 and 1,2mm thickness.

Alaska Yellow Cedar is our second specialty timber specie.

Alaska Yellow Cedar is our second specialty timber specie. At our mill in Canada we saw a full range of products from standard sizes and grades to specialty boatplank and deck products in lengths of over 10 meter.

Alaska Yellow Cedar is one of the most valued timbers in the world. Those craftsmen who have worked with it have all come back for more. The moderate hardness and extraordinary evenness of grain makes it easy to work with. It is incredibly durable and can be used without paint or varnish exposed to the harsh conditions.

Full list of Alaska Yellow Cedar products . . .

Standard products

- 2x4, 2x5, 2x6 and wider. STK, D and C-Clear.

Specialty products

- Boat planking – sawn to your specification, lengths up to 11,8 meter.

- Yacht deck

- Concert hall stage flooring

- Acoustic flooring

- Temple beams and timbers

- Architectural beams

- Fine furniture grade

- Convex-Concave boatstrip

- Custom veneers

- Arrow stock

- Table slabs

Lock, stock and barrel: Cedrela, Sipo Mahogany, Butternut, Locust, Western Red Cedar, Oregon Pine and White Pine.

What makes our life at Touchwood so extraordinary is that we are surrounded by hyper creative people who come to us for the unusual. Some wood species for historically authentic restorations are no longer commonly available, certainly not in any volume and length. Other products like sawn veneers require expertise which few companies in the world today can offer. Some we keep in stock, some we manufacture to order, others we will gladly help you source. Unusually hard to find is the common denominator for our specials.

Full list of specials . . .

Cedrela odorata

One of the finest boatbuilding timbers ever ! In the old days it was the preferred planking stock for yards such as Abeking & Rasmussen, Børresen, Sangermani, Nevins and many others. Before the introduction of glass fiber is was the wood of choice for the delicate rowing skulls racing on the rivers and the Olympics. What separates Cedrela is the combination of extraordinary dimensional stability, lightness and strength. It is universally loved for its appearance, warm brown and maturing over time to an even higher beauty. The availability in the highest quality and longer lengths is very limited but at our mill in Holland we always keep a stock of boatbuilding dimensions.

Sipo mahogany

Our main line in Sipo consists of sawn veneers which we supply to the yards restoring classic powerboats like the Riva, Boesch, Hacker and Chris craft. For these projects we keep precision quarter sawn veneers in stock at 6,5mm thickness and lengths up to 11,7 meter. These veneers are also used for the yards building luxury tenders and commuters. We select our own veneer logs for these products and from these same logs we cut a limited volume of quarter sawn lumber for yacht interiors and boat planking stock.

Butternut (junglans cinerea)

As a service to yards restoring classic yachts built at the beginning of the 20th century on the USA East Coast we keep a small inventory of Butternut. This was the specie of choice for Nathanael Herreshoff and Olin Stephens. A fungal disease has brought down the old stands and the availability today is extremely rare. We try to keep our inventory available for special projects only.

Locust (robinia pseudoacacia)

Locust is well known is a small circle of specialist boat builders. It is treasured for it’s extraordinary durability and strength. Although it is hard, the fibers are long and very resilient which makes it highly suitable for steam bending. Locust is used for frames, the backbone, floors, pin rails, stanchion posts and yacht blocks. It is also the number one choice for doublers, backing and reinforcements in Sitka spruce spars. At our mill in Holland we always keep a small inventory of long lengths, even up to the super rare length of 6m.

Western Red Cedar (Thuja plicata)

We have beautiful tight grain Western Red Cedar from our mill in Canada and keep an inventory of both quarter sawn and flat grain boards at our mill in Holland. WRC is extensively used for strip planking and wood core construction. However, we have also supplied the elite top grades for interior paneling and decorative woods. Occasionally we have WRC boatplank available in lengths from 8 to 12 meter. If you have special requests then please contact us, we are able to cut almost any dimension and grade for your project.

Oregon pine – Douglas fir (Pseudotsuga menziesii)

Our sawmill is located about 600km North of the Northern boundary of Douglas Fir growth, so unfortunately there is none to be found in the forests which surround us. As a service to the yards we do keep a small inventory of Douglas fir at our mill in Holland. We only store quarter sawn and rifts, always limiting ourselves to the elite quality. If you need larger volumes then please contact us, if and when we have a suitable source for high quality we will gladly discuss the options with you.

White pine (pinus strobus)

White pine was a specie used for yacht decks during the Victorian era. Few yachts of the era have survived, even fewer have been restored. For us the story with White pine started when Paul Goss bough Ayrshire Lass, a 1887 William Fife II gaff cutter. For her decks the original species had to be sought and we found a small mill who had a few suitable logs. Later the 1887 Beroe designed by George Lennox Watson needed the same for her decks. We keep a very small inventory and White pine is just one of those species which we will try to source for you project.

The chain of custody.

From the forest to your yard, mill or studio.

The key elements to grow elite quality

The quality of Sitka spruce largely depends on its origin. The best quality grows in the far Northwest of British Columbia and the Southeast of Alaska. The climate in the pacific Northwest coastal regions is made for Sitka spruce. The high latitude shortens the length of the summer season and thus the rate of growth. Abundance of rain, proximity to the sea, lakes and rivers are other essentials, as are the soil type and condition.

Expert selection of logs

This is why we personally travel the forests, to see where the trees grow, to know the location and conditions, the exposure to weather, so see how canopies develop. We talk to the fallers to explain the quality characteristics needed by our buyers.

Each log is unique and traceble

Our sawmill in Terrace, Northern British Columbia is situated close to the ports where we can dewater the logs and truck them over to our sawmill. All our logs have individual unique tag numbers and these tag numbers are marked on each board sawn from that log. This way we know the origin of each individual board that is shipped from the mill. During the processing of the boards at the mill in The Netherlands, we continue this tagging and identification process, always tracking and marking the individual pieces.

Verifying the mechanical properties

At our in-house testing lab we verify the mechanical properties of each log by testing multiple samples from each log. This way we know the typical axial compression strength and density of each log. This is especially important for aircraft builders and the yards building high end yacht racing spars.

Dewatering the logs in Northern British Columbia

The sawmills.

The Dutch mill

Touchwood BV

Our sawmill in Holland is where we remanufacture the product which is shipped from the mill in Canada. Here we select, grade, saw and plane the boards to exacting specifications of our buyers.

Depending on the time of year we always hold between 300 and 500m3 of sawn Sitka spruce in a variety of dimensions and sorts.

A custom built sawing line allows us to plane, edge, rip to width and cut to length while all heavy material is carefully handled with vacuum lifting technology. The main rip line is designed for tension relief cutting and is used for almost all products and yards we supply. A thin kerf band resaw is installed for precision cutting of wood for the musical instrument builders.

Based on the premises of Houtindustrie Schijndel – the premier custom remanufacturing mill in The Netherlands – provides us a multitude of advantages. We have access to 1200m3 dry kilns, a vacuum kiln, 10 dedicated moulder and planer lines, 2 resaw lines, optimising cross cuts, laminating lines with a combined capacity of over 120.000m3 per year, and a well-oiled logistical infrastructure where trucks are loaded and unloaded efficiently.

At Schijndel we also run the administration for both the Dutch and the Canadian operation. Here we also have the wood testing laboratory.

The Canadian mill

Touchwood Pacific Sawmills Ltd

Back in 2002 we started to build our first sawmill in Alaska. A joint venture on Gravina Island which tied in really well with road building, logging and the main sawmill on the island.

Then in 2016 we decided to build a new and more sophisticated specialty sawmill in Terrace in the Pacific Northwest of British Columbia, Canada. Being in Terrace, means we are ideally located between the ports of Prince Rupert and Kitimat.

The design of the mill was based on all we had learned over the years, the demand for long length high quality timber. The demand for specific sawing patterns and specialty products with high dimensional accuracy. We are fully independent with our own power grid serving the mill, the maintenance, the saw filing room and offices.

As the focus is on processing highly valuable logs and timbers, there is a great emphasis on accuracy, on avoiding mechanical damage and obtaining a high surface quality.

The headrig and carriage for primary breakdown are built by Bögli in Switzerland, the focus being on precision and quality rather than quantity.To avoid mechanical damage when handling the huge boards and slabs we installed at vacuum robotic handling system. This way pieces of up to 1,5 ton are handled with the greatest care and the risk for mechanical damage is reduced to and absolute

Our mill offers specialty products cut to order as well as a full custom cut service. With our own 5 Hectare dry sort and log storage we have ample space to individually build, separate and deck out the logs for our clients.

Our maximum timber sizes at the mill are:

Maximum log / timber length: 60 ft – 18 meter

Maximum length edged: 42 ft – 12,6 meter

Maximum log diameter: 80 Inch - 200 cm

Maximum thickness: 24 Inch - 60cm

More about the Canadian mill on touchwood-sawmills.com

Environmental.

For our remanufacturing process

we do not use any fossil fuels.

Our company is based on the premises of Houtindustrie Schijndel, the premier custom remanufacturing mill in The Netherlands. Here we make use of the internal grid where all the required energy is generated from the wood waste such as sawdust, shavings and offcuts. In addition some 9,000m2 of solar panels have been installed on the roofs of the production and storage buildings.

Houtindustrie Schijndel was the first woodworking company in The Netherlands to convert to green energy. A large 20mW biomass conversion plant was installed generating overheated steam which powers a 1,3mW Steam turbine. The secondary steam coming from the turbine is condensed to water providing the thermal energy needed to heat the dry-kilns, offices and production facilities.

The 6.000m3 biomass storage silos provides a closed system, the most environmental of its kind. Houtindustrie Schijndel continues to invest in green energy and technology and today the premises produces more energy than it consumes, it supplies green electricity to the grid as well as thermal energy to the surrounding houses.

Meet the team.

Need help? Questions? Get in touch!

John Lammerts van Bueren

Owner & general manager

Founder of Touchwood, a life of racing and cruising wooden sailboats around the world. After owning an engineering company designing production lines for the wood industry, he realized his dream to combine his free time passion with work time passion. And so, he built his first sawmill in Alaska to supply wooden boatyards around the world. Later a new mill was built in the North of Canada with expanded capacity to also serve the wooden aircraft and musical instrument builders. Super specialized in Sitka spruce and Alaska Yellow Cedar, two of the most wood species which draw and connect the most creative and amazing craftsmen. As wood expert, engineer and champion sailor he had and has a deep involvement in the development of racing spars.

Phone Europe: (+31) 6 53 19 53 53

Phone Alaska & Canada: (+1) 250 641 4599

Joep Verheijden

Chief sawyer & log puchase

Chief sawyer and log buyer who divides his time between the mill in the Netherlands and the mill up North in Canada. He has intimate knowledge of the entire process from the forest to the mill, he is and expert in reading the logs and flitches and has the rare talent in calling the right cut line to make a perfect product. Loves the time up North, will never miss an opportunity to see the Humpback whales, loves being out there on the water and in the mountains. A man of so many talents and of great creativity.

Mobile phone: (+31) 6 53 47 37 16

Ernst Boucher

Aircraft spruce

A life time passion for flying, an active and passionate glider pilot who flies his own Jodel single engine plane as often as he can. Many years ago, Ernst called Touchwood when he was building his own plane, he connected, got the bug and never looked back. Of course his main expertise is aircraft spruce for new build and restorations. As an expert aviation historian he loves to hear and learn from the old warbirds and will always have a tale to tell. Ernst is involved in all strategic and business development plans. A bright and creative mind and he too divides his time between the mill in Holland and Canada.

Mobile phone (+31) 6 21 28 21 15

Mike van der Ploeg

Saw doctor & mill manager Canada

Our saw doctor and the heart and soul of the mill in Terrace, Northern British Columbia. Mike immigrated from Holland at a very young age and grew up in Canada. His relentless attention to detail and perfectionism drove his life time career as head in the filing rooms at some of the best sawmills up North. At Touchwood Pacific Sawmills he divides his time between the filing room and tinkering on ideas to build or improve equipment and make the mill a better place. And then there are the sawmill dogs, they love him as much as he loves them. And, if Mike is not at the mill you will find him out on the ocean where the fish fear him for all the right reasons.

Mobile phone (+1) 250 631 8158

Pia van Veen

Administration & accounts

Nothing escapes her attention, she’s been around us for almost 30 years, taking care of accounts, books and payments. She has seen ideas and dreams become reality, she has seen all the ups and downs that come with running companies on different continents. Through all the years and dynamics one thing never changed, Pia was there. If she wasn’t, she would be with her Leon, somewhere in Scotland or Wales, enjoying Britain, that is, was and will always be her escape from a work-a-day world.

Last, but not least...

No question is too big or too small for us.

We are here to help you build your dream. For the big corporate entrepreneur, the craftsman or the enthusiast building his dream in his basement. We are very flexible, except when it comes to the quality of our work.